Contact : Ms.Fancy

Contact : Ms.Fancy

Tel : +86-15067869100

Fax :

Email : welltechcn@hotmail.com

Skype : whatsApp: +86 15067869100 Wechat ID : welltechcn

Partners:

Alibaba Website:

Aliexpress Store Website:

http://www.aliexpress.com/store/628551

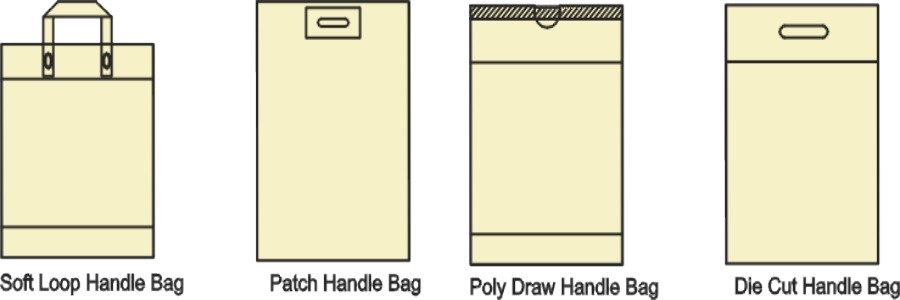

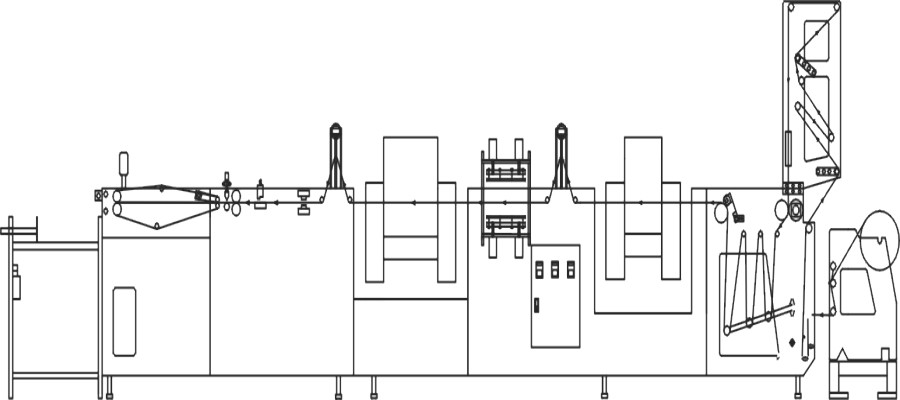

WTFM-800 Fully Automatic Computer-Controlled Multi-fuctional Handle Bag Making Machine

Category : Plastic Bag Making Machine

Model : WTFM-800 Fully Automatic Computer-Controlled Multi-fuctional Handle Bag Making Machine

OnLine Service:

Print this Page

Print this Page

|

Bookmark this

Bookmark this

|

Skype Online

Skype Online

|

E-mail Us

E-mail Us

|

PDF Download PDF Download

|

|

| Prev Next | |

| Description | Send Inquiry |

|---|

Related products