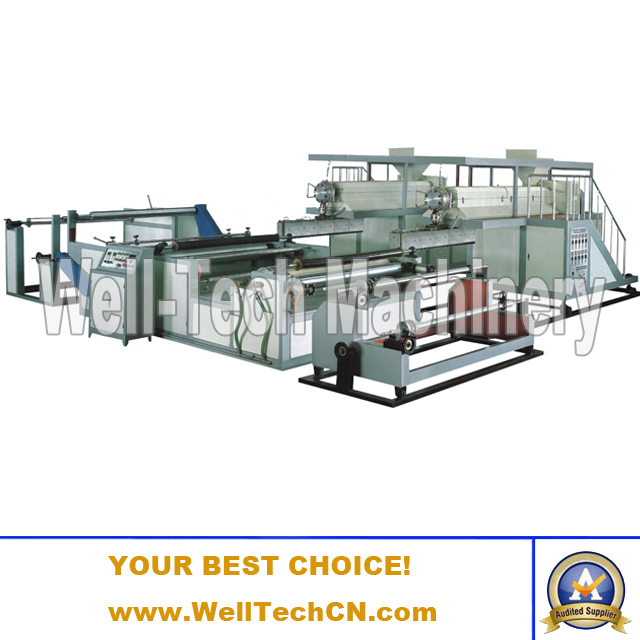

Bubble film machine adopts once-through shaping technique, thus has high efficiency and excellent product quality. This machine set has such features as scientific and reasonable structure design, smooth and reliable running and convenient operation and maintenance. Polyethylene air-cushion film (also called polyethylene bubble film), which is divided into two kind: ordinary polyethylene air-cushion film and composite polyethylene air-cushion film, is a kind of packing material which has been widely used at present. It not only has good cushioning effect, shock resistance and heat-sealing performance, but also has such advantages as good corrosion resistance and transparency, etc. So it has been widely used for packing, household wares, post parcel, bicycle, polyurethane furniture, etc.

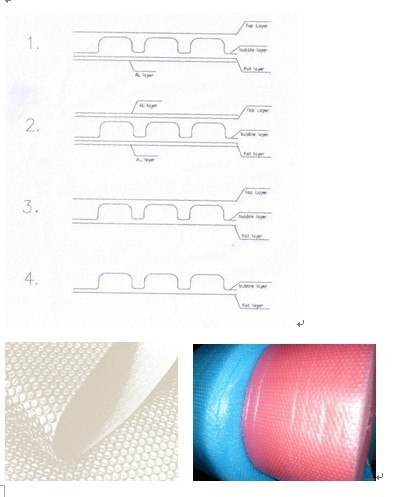

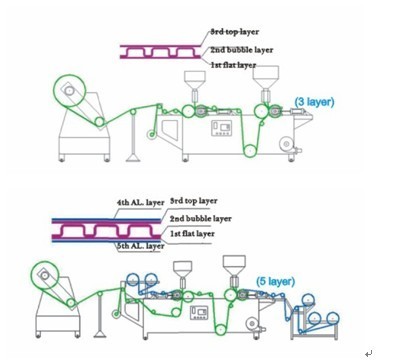

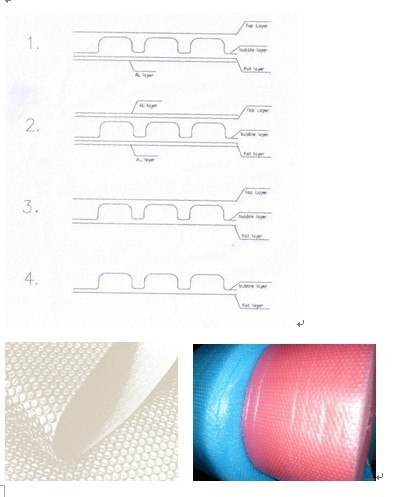

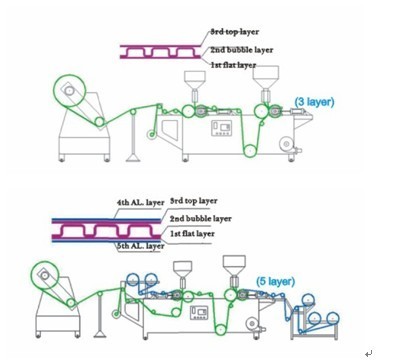

Using one extruder can produce two layer, using two extruders can produce three layer to five layers with laminating layers.

Add one rewinder part, can compound one layer EPE or aluminum foil, add two rewinder part can compound two layer EPE or Aluminum foil.

Optional Equipments:

1) Rewinder I (produce four layer)

2) Rewinder I + Rewinder II (produce five layer)

3) Auto loader

4) Auto dryer

5) Electric screen net changer

6) Air shaft roller (if you want to use paper tube)

7) Bubble roller (different bubble size from the one install in the machine)

Material: LDPE

You can use new material, also can use recycled material.

If you want to produce color bubble film, you can add color masterbatch.

Main Technical Parameters:

|

Model

|

WTPEG-1000

|

WTPEG-1200

|

WTPEG-1500

|

WTPEG-1600

|

|

Diameter of screw

|

φ60mm , φ50mm

|

φ65mm , φ55mm

|

φ75mm , φ60mm

|

φ75mm , φ60mm

|

|

L/D Ratio

|

28:1

|

28:1

|

28:1

|

28:1

|

|

Screw & Barrel material

|

38 CrMoALA

|

38 CrMoALA

|

38 CrMoALA

|

38 CrMoALA

|

|

Width of T-die head

|

1150 mm

|

1350 mm

|

1650 mm

|

1750 mm

|

|

Heating way

|

Casting-aluminum heating device

|

|

Width of bubble roller

|

1080 mm

|

1280 mm

|

1580 mm

|

1680 mm

|

|

Width of products

|

1000 mm

|

1200 mm

|

1500 mm

|

1600 mm

|

|

Thickness

|

0. 06-0.25 mm

|

0. 06-0.30 mm

|

0. 06-0.30 mm

|

0. 06-0.30 mm

|

|

Main motor

|

15 kw , 7.5 kw

|

15 kw , 11 kw

|

18.5 kw , 15kw

|

18.5 kw , 15kw

|

|

Traction motor

|

1.1 kw*2

|

1.1 kw*2

|

1.5 kw*2

|

1.5 kw*2

|

|

Total power

|

86 kw

|

95 kw

|

112 kw

|

112 kw

|

|

Re-winder

|

Turnover duplex turret rewinding type

|

|

Max. output

|

80 kg/h

|

100 kg/h

|

150 kg/h

|

150 kg/h

|

|

Linear speed

|

1000 m/h

|

1000 m/h

|

1000 m/h

|

1000 m/h

|

|

Model

|

WTPEG-1800

|

WTPEG-2000

|

WTPEG-2500

|

|

Diameter of screw

|

φ85mm , φ65mm

|

φ95mm , φ75mm

|

φ120mm , φ90mm

|

|

L/D Ratio

|

28:1(L/D)

|

28:1(L/D)

|

28:1(L/D)

|

|

Screw & barrel material

|

38 CrMoALA

|

|

Width of T-die jead

|

1950mm

|

2150mm

|

2650mm

|

|

Heating way

|

Casting-aluminum heating device

|

|

Width of bubble roller

|

1880mm

|

2080mm

|

2580mm

|

|

Width of products

|

1800mm

|

2000mm

|

2500mm

|

|

Thickness

|

0. 06-0. 30mm

|

0. 06-0. 30mm

|

0. 06-0. 30mm

|

|

Main motor

|

30kw , 15kw

|

37kw , 18.5kw

|

54kw , 37kw

|

|

Traction motor

|

1.5kw*2

|

1.5kw*2

|

1.5kw*2

|

|

Total [ower

|

141kw

|

158kw

|

235kw

|

|

Re-winder

|

Turnover duplex turret rewinding type

|

|

Max. output

|

180 kg/h

|

220 kg/h

|

300 kg/h

|

|

Linear speed

|

900 m/h

|

800 m/h

|

650 m/h

|

Contact : Ms.Fancy

Contact : Ms.Fancy

Print this Page

Print this Page

Bookmark this

Bookmark this

Skype Online

Skype Online

E-mail Us

E-mail Us

PDF Download

PDF Download